Living Environment Division, Farm Equipment · Soil Improvement · Water Filtration Materials etc.

The Living Environment Division develops various products such as gardening supplies, green houses for agriculture and manual earth auger drills. These products are used by those who farm as a hobby as well as professional full-time farmers. According to our research, KOBAYASHI TOOL MFG has the largest market share in the manual earth drill industry in Japan. Located in Niigata prefecture, famous for it’s agriculture, we are proud of our safe, easy to use, durable products. Using KOBAYASHI TOOL MFG’s experience and skills in tool creation and manufacturing, we are pleased to offer the highest quality farming equipment products available.

Product Information

Taicho Stone

Gardening · Horticulture · Flowerpots etc.Forged Aeration Tine

Triple blade structurePipe Crimping Tool

Allows for the crimping of two pipes into a single long pipe.Manual Earth Auger Drill

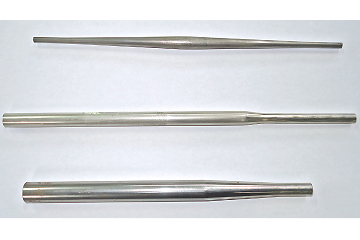

Makes well rounded beautiful holesSwaging Process (Rotating Cold Forging Process)

The swaging process (rotating cold forging process) is a process in which a divided die rotates and is hammered to squeeze the outer diameter of a round bar or pipe material.

The Benefits of Cold Forging

- Cost reduction can be achieved by eliminating material waste and loss.

- The strength of parts can be improved by work hardening.

- Environmentally friendly

Processing Capacity

| Minimum Diameter | Material Outer Diameter | φ10mm (Pipe thickness 0.8-3 mm) |

| Material Outer Diameter | φ10mm (pure material) | |

| Maximum Diameter | Material Outer Diameter | φ36mm (Pipe thickness 0.8-3mm) |

| Material Outer Diameter | φ30mm (pure material) | |

| Length | Shortest | 90mm |

| Longest | 700mm |

Three Features

A Beautiful Surface Finish

Material costs are reduced because material powder is not produced during the cold forging process. It creates an extremely beautiful processed surface when compared to conventional cutting processes. Metal tubes and solid materials etc. are formed by hammer processing. A wide range of dimensions are possible including steel pipe columns.

An Increase in Strength

Surface roughness can be strengthened by high-speed striking technology through rotary forging. The strength of parts are increased by work hardening. It is also a used wodely in automotive part manufacturing.

Compatible with a wide variety of materials

It is possible to use cold forging when working with hard to process materials such as titanium and stainless steel. Applicable materials include: Pure titanium, titanium alloys such as beta titanium, NT alloy, as well as rubber metals, stainless steel, aluminum, nickel silver and more.