The Overwhelming Durability Achieved by Forging Technologies

Since its founding in 1963, KOBAYASHI TOOL MFG.Co., Ltd. has been good at manufacturing tools and blades via “Precision Hot Forging”.

Our craftsmen who have no compromises manufacture blades by forging and our blades are now active in the hands of engineers around the world for over half a century.

A thing that support us today today is the technology of “precision hot forging” which can not be imitated by other companies.

It is almost impossible for other companies to manufacture thin blades using a forging process. We realized this by utilizing our own technology. Unlike products from other manufacturing methods, please expect our products that have excellent durability due to our unique forging process.

Performance Test Results

The microphotographs (50 magnification) below show the comparison of endurance test result ( 500 times cutting test of 325 sq.-mm copper wires) among;

(a) Forged cutter (our products),

(b) Lost wax molded cutter (Taiwan product)

(c) Blanking machined cutter (made from plate material) (Chinese product)

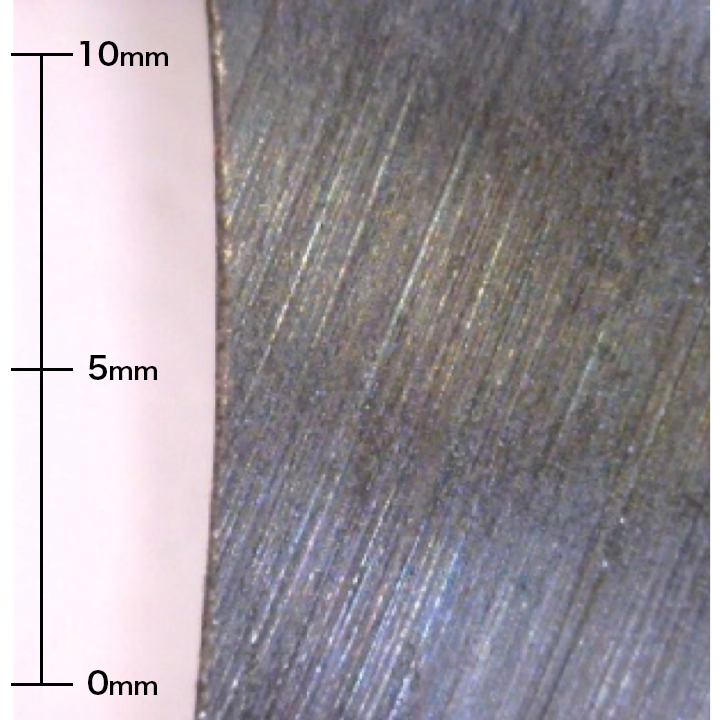

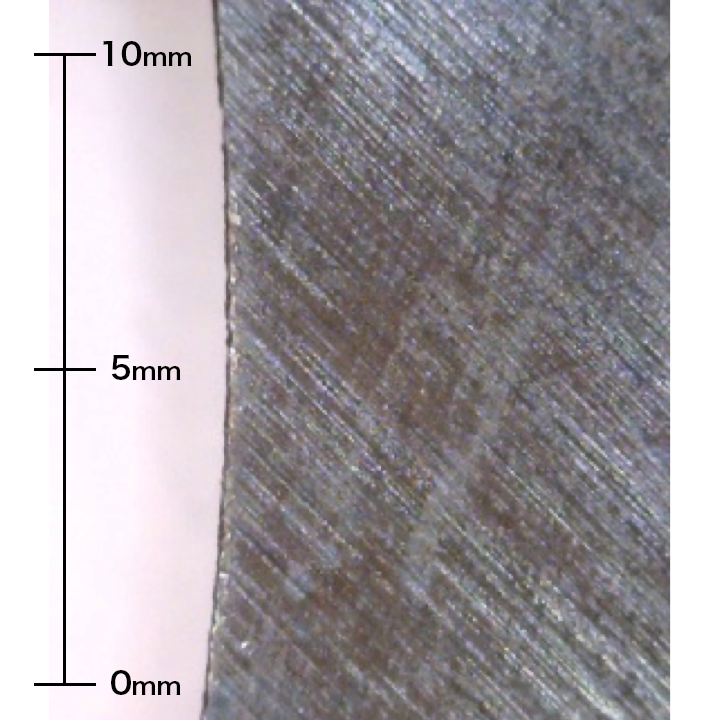

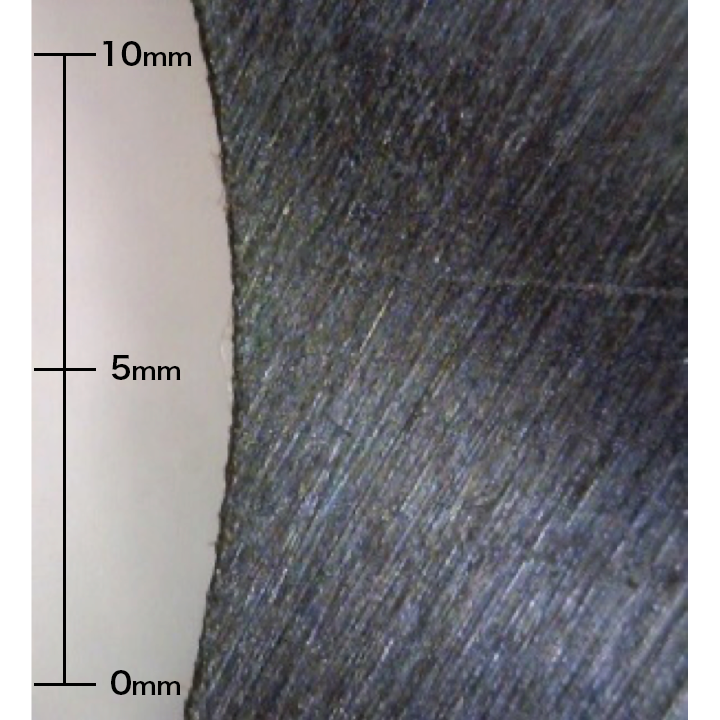

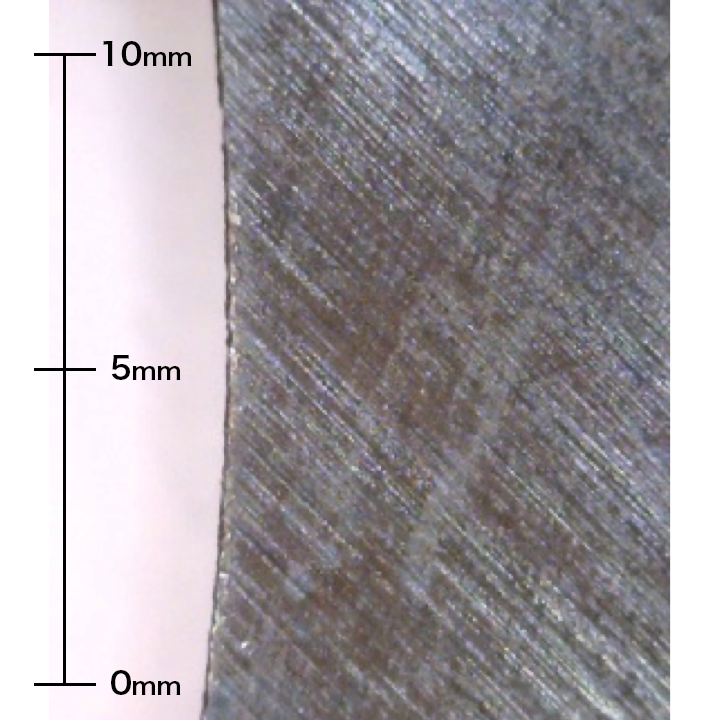

(a) Forged blade (our product)

Before cutting test

After 500 times cutting test of 325 sq.-mm copper wires

White brighter part along the edge after the test shows the black surface finishing (corrosion resistance) being grinded off.

The edge is not lost at all after the test. Sharpness of blade is maintained almost same as that before test.

The hairline pattern on the blade surface is scratch mark given by copper wire during the cutting test.

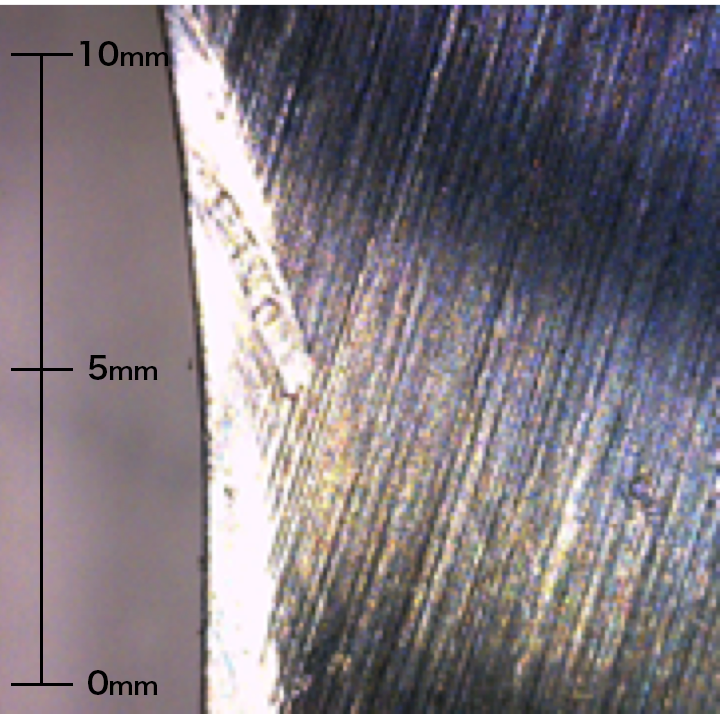

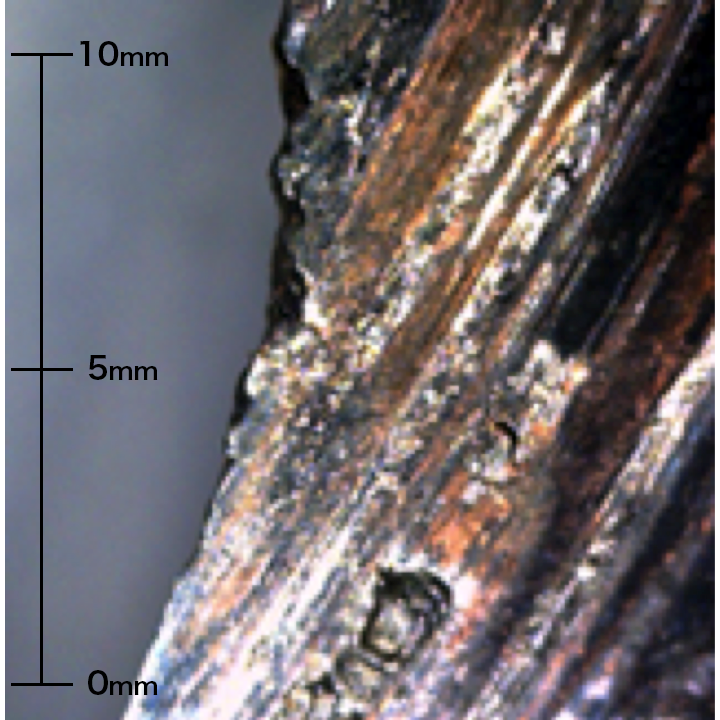

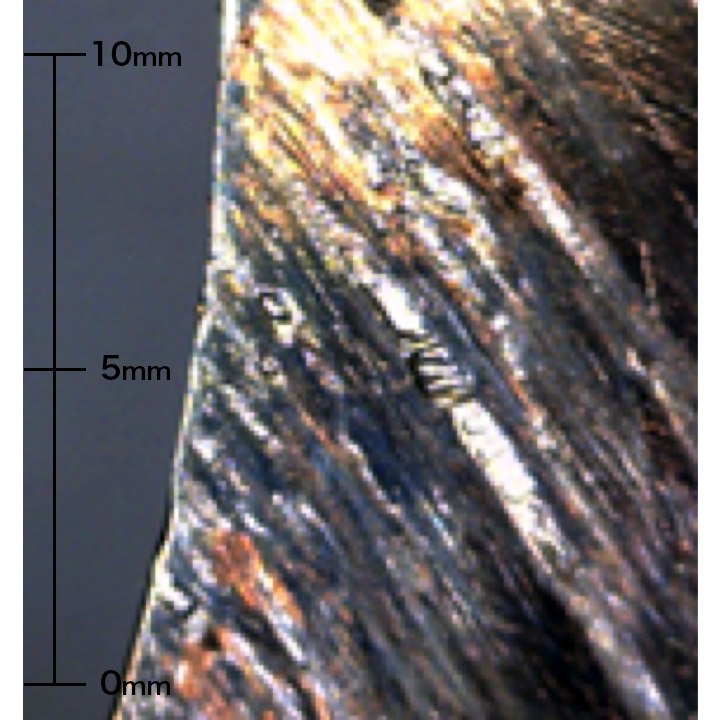

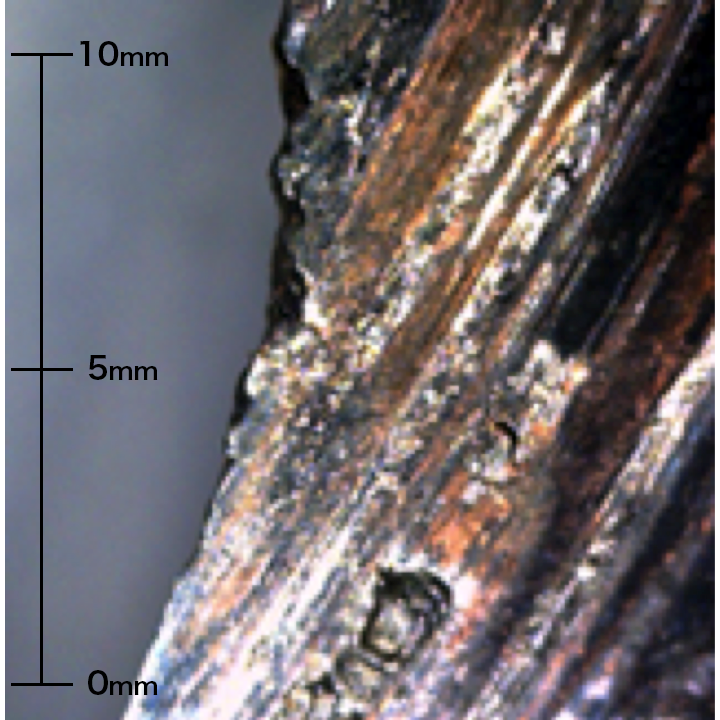

(b) Lost wax molded cutter (Taiwan product)

Before cutting test

After 500 times cutting test of 325 sq.-mm copper

The edge (grinded part) is completely lost and broken.

It is afraid that the service life might come to the end before long if continuing usage.

The many ditches on the blade surface are scratch marks given by copper wire during the cutting test.

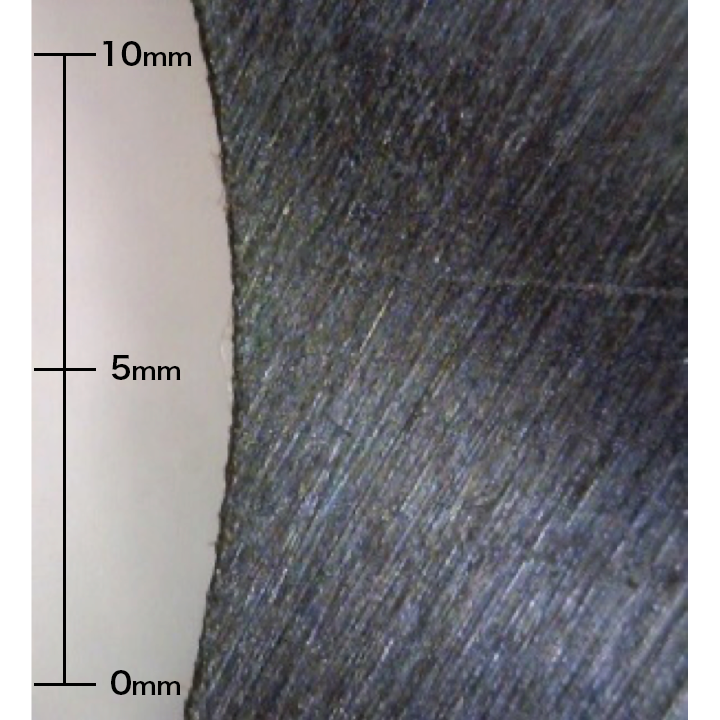

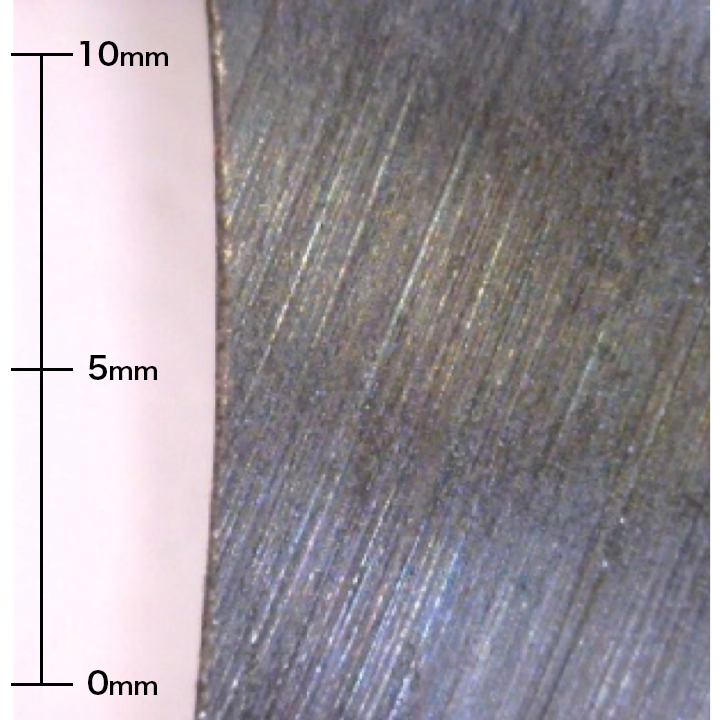

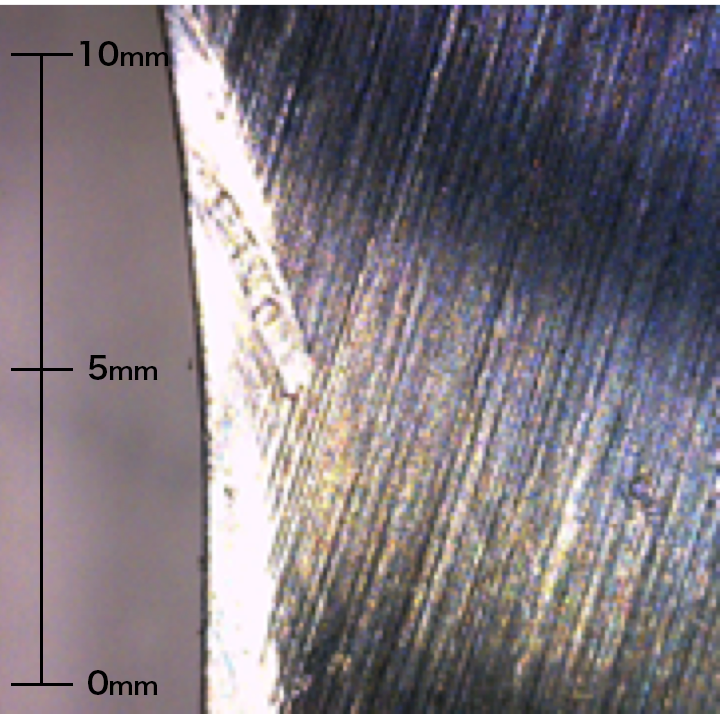

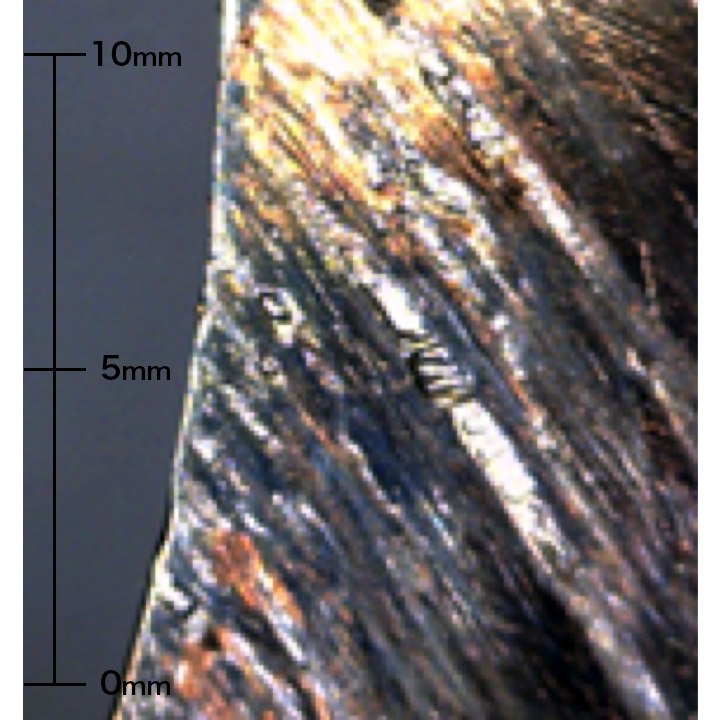

(c) Blanking machined cutter (made from plate material)

(Chinese product)

Before cutting test

After 500 times cutting test of 325 sq.-mm copper

When the test reached to 400 times cutting, this cutter was broken (spring on handles is broken).

The test was discontinued and this photo shows the blade condition at this time.

The edge (grinded part) is completely lost and broken.

It is afraid that the service life might come to the end before long if continuing usage.

The many ditches on the blade surface are scratch marks given by copper wire during the cutting test.

What KOBAYASHI TOOL MFG Cherishes

High Quality and Reasonable Pricing

The quality of blades made by forging is incomparable to those made by casting methods (Lost-wax). From the beginning of blade production, reports of blade damage are non existent. Moreover, we have confirmed all operations after their completion. We pursue compactness and maintainability by utilizing the design technology of experienced development staff.

With a strict management system, we aim to pursue higher quality product creation. We are currently promoting research and development of patented products day and night.

Our products are now widely exported to the United States and other Asian countries etc.

Since functional parts can be repaired, they can be used for long periods of time. We maintain our production of high quality, reliable technology for long term use.

Responsive Capabilities in New Circumstances

In the product field of OEM development and ratchet cable cutter, we are proud to be one of the world’s leading tool manufacturers in terms of rapid development capability, patent possession and high durability by forging.

Our competitive advantage are quality assurance, flexible response, and responsibility for supplying tools with made in Japan quolity.

All for the Consumer

We have supplied OEMs to tool manufacturers all over the world.

While having provided the safest and most comfortable tools that can have been used by consumers around the world, small and lightweight tools and lightwork have been required. We respond quickly to the urgent demands of our clients such as end users and manufacturers, and we have become the only manufacturer of the forged manual ratchet cable cutter in Japan.

Before cutting test

Before cutting test

After 500 times cutting test of 325 sq.-mm copper wires

After 500 times cutting test of 325 sq.-mm copper wires Before cutting test

Before cutting test

After 500 times cutting test of 325 sq.-mm copper

After 500 times cutting test of 325 sq.-mm copper Before cutting test

Before cutting test

After 500 times cutting test of 325 sq.-mm copper

After 500 times cutting test of 325 sq.-mm copper