KOBAYASHI TOOL’s Hot Forging Technology

3 reasons why we are selected

1Commitment to Quality

We manufacture important parts that require the strength provided by hot precision forging with an air drop hammer. Our products have quality and value that only we can produce. The striking force of the hammer is adjusted by pedal operation. Our forging process takes time and labor and requires experience for fine adjustments to temperature, speed and pressure. We take pride in the technical skills and knowledge that allows us to create a rare product that can only be made here with feeling of made in Japan pride in our hearts.

2Consistent Quality Control

Our iron working department has acquired the International standard ISO9001 Authentication. Based on this international standard we have established a strict quality control system. From inspection upon the reception of goods to processing inspection through to the final inspection before shipment, we produce our products according to our fine tuned system that insures defective products do not pass through any stage of our inspection process. Furthermore, many of our production line staff hold national qualifications in professional forging skills. With our reliable technology and knowledge, we promise to produce high precision products for your every need.

Our production facilities are also equipped with measurement equipment such as venire calipers, micrometers and wet magnetic particle flaw detectors are installed within the factory. We also have the capabilities to make measurements with a Coordinate Measuring Machine(CMM) and Hardness Tester.

3Flexible Production System

With a focus on hot forging, our company offers machining and assembly processing, heat treatment, shot blasting, and various inspection processes. We do this with a tremendous amount of responsibility and commitment. Our manufactured parts are chosen for important machine parts which require strength such as the safety components of construction machinery, automobile parts, truck parts, motorcycle parts, power transmission parts and various gear systems. We supply parts all over the world through numerous major companies. We are also involved with many partner companies. In addition to hot forging, we are also able to do perform cold forging and special forging. We have the facilities and skills to manufacture most parts and products. Please do not hesitate to consult us.

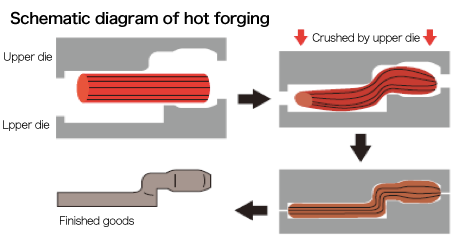

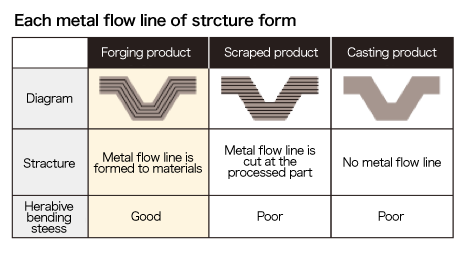

Hot forging achieves overwhelming durability. More so than other manufacturing methods.

It is almost impossible for other companies to manufacture thin blades using a forging process. We realized this by utilizing our own technology. Unlike products from other manufacturing methods, please expect our products that have excellent durability due to our unique forging process.

See Our Quality

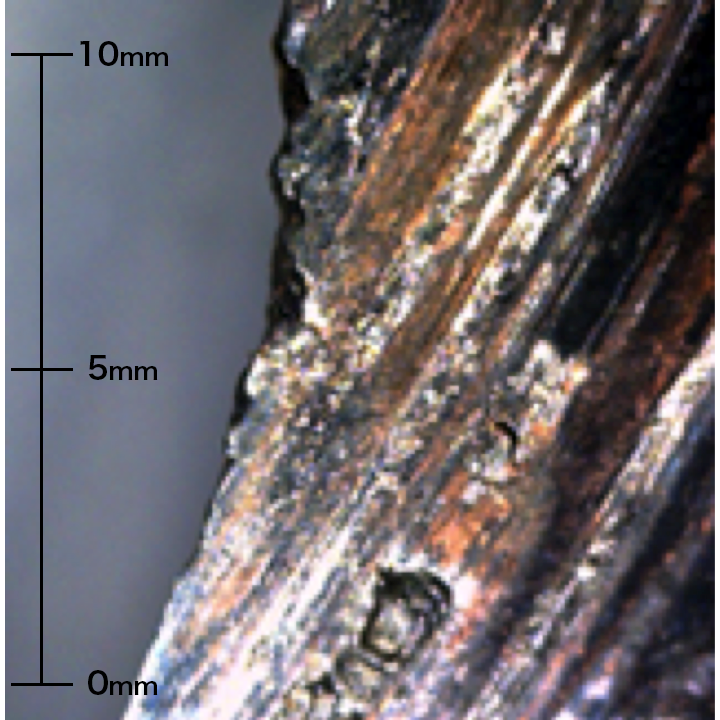

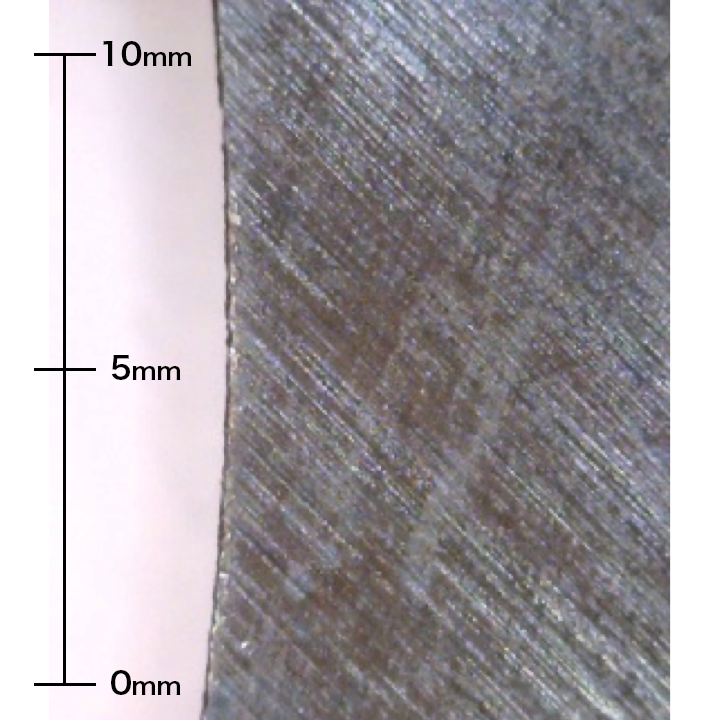

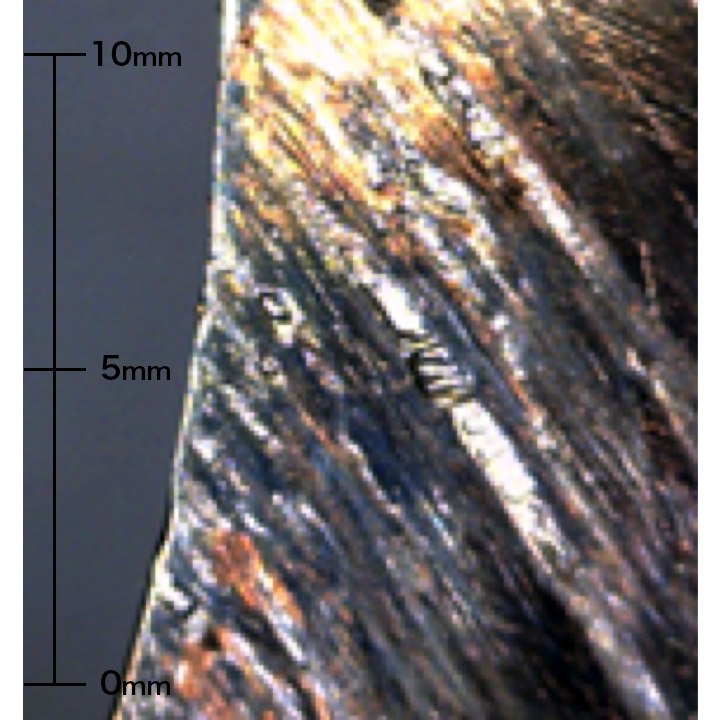

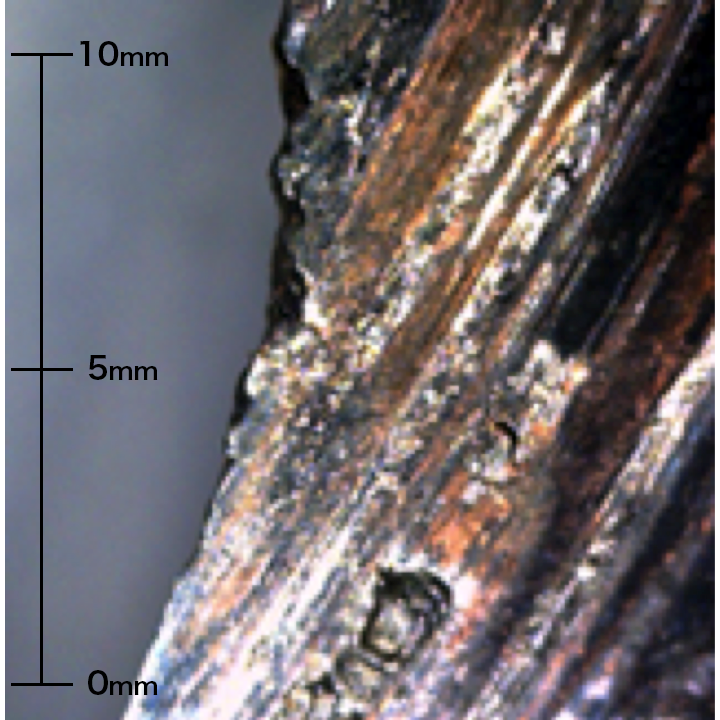

The microphotographs (50 magnification) below show the comparison of endurance test result ( 500 times cutting test of 325 sq.-mm copper wires) among;

(a) Forged cutter (our products),

(b) Lost wax molded cutter (Taiwan product)

(c) Blanking machined cutter (made from plate material) (Chinese product)

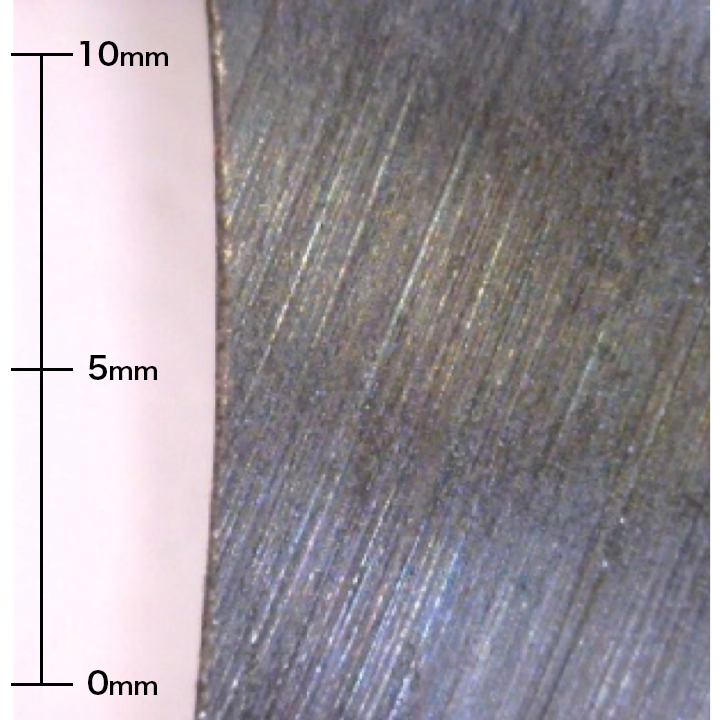

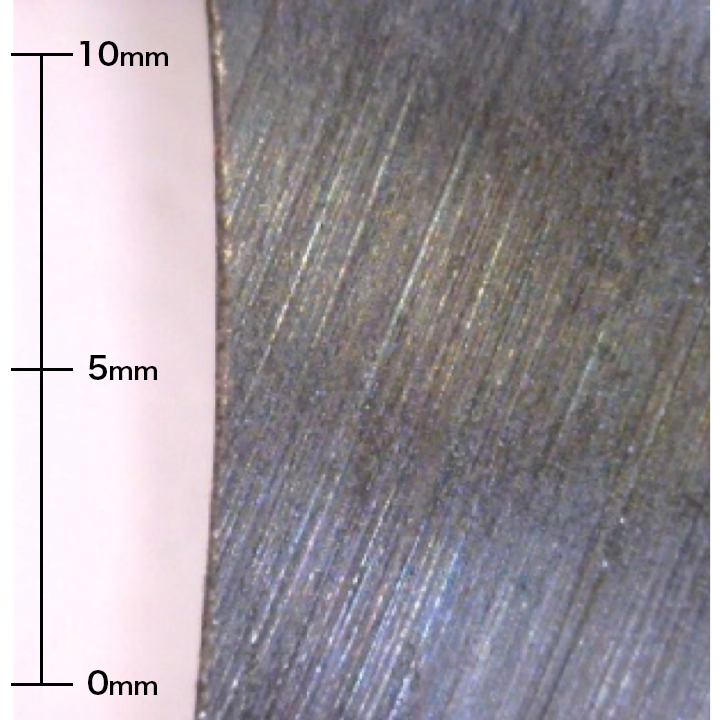

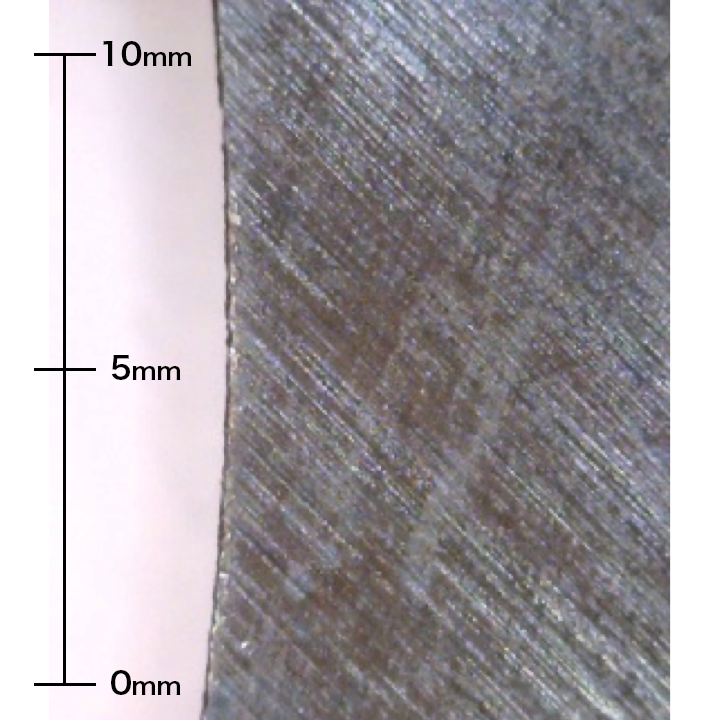

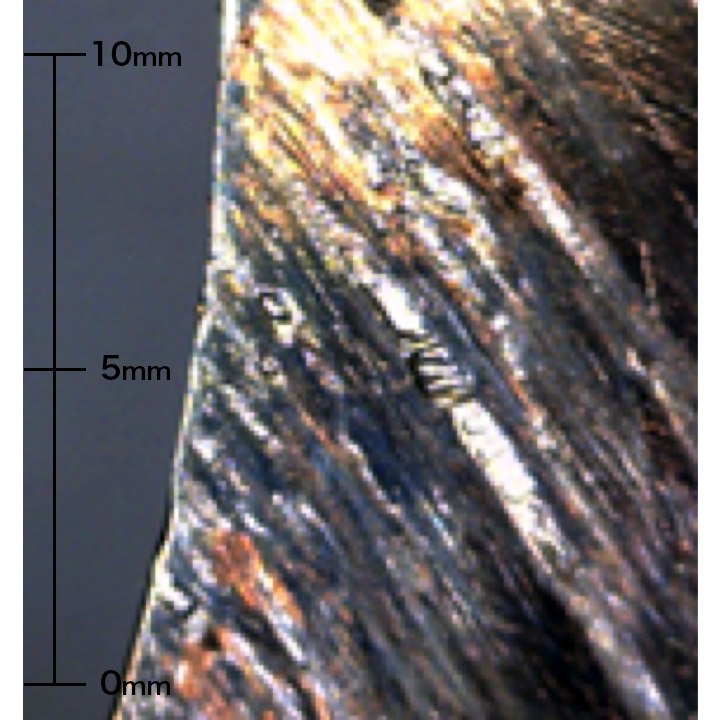

(a) Forged blade (our product)

Before cutting test

After 500 times cutting test of 325 sq.-mm copper wires

White brighter part along the edge after the test shows the black surface finishing (corrosion resistance) being grinded off.

The edge is not lost at all after the test. Sharpness of blade is maintained almost same as that before test.

The hairline pattern on the blade surface is scratch mark given by copper wire during the cutting test.

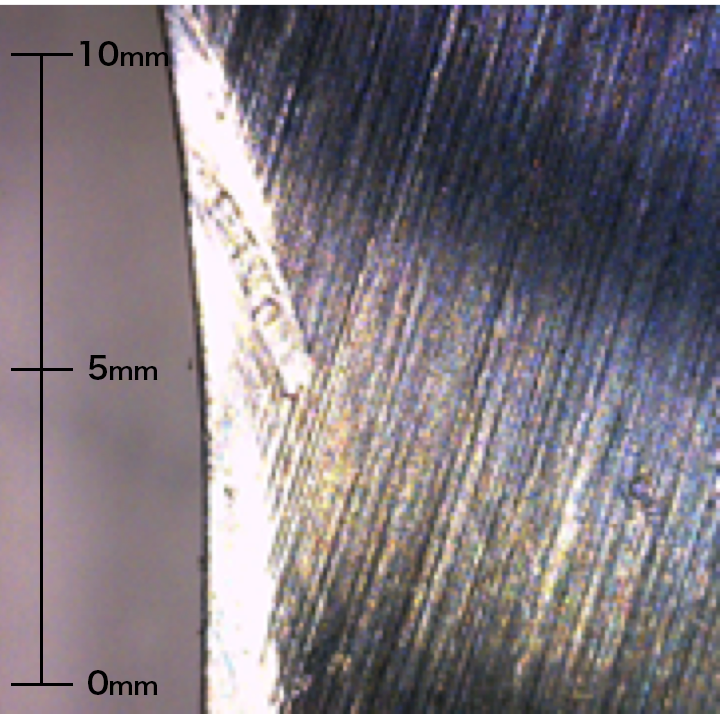

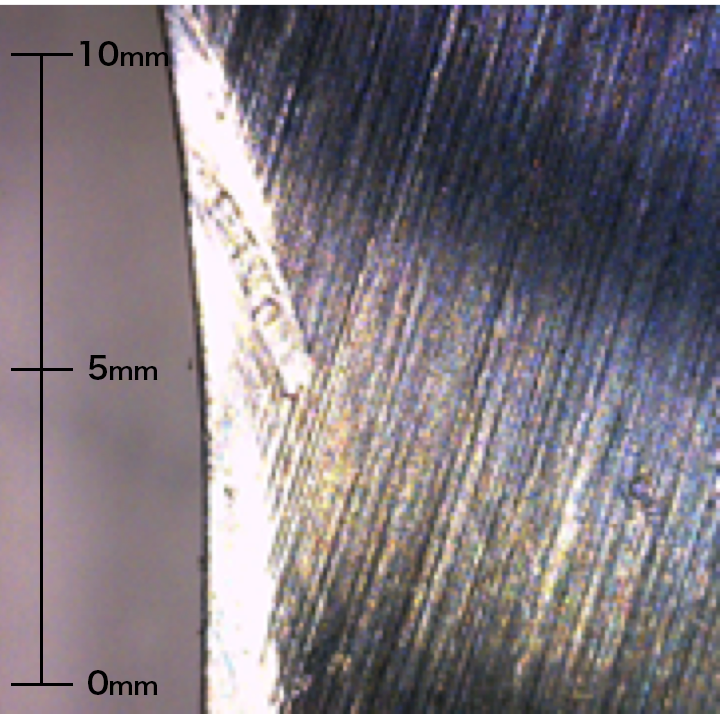

(b) Lost wax molded cutter (Taiwan product)

Before cutting test

After 500 times cutting test of 325 sq.-mm copper

The edge (grinded part) is completely lost and broken.

It is afraid that the service life might come to the end before long if continuing usage.

The many ditches on the blade surface are scratch marks given by copper wire during the cutting test.

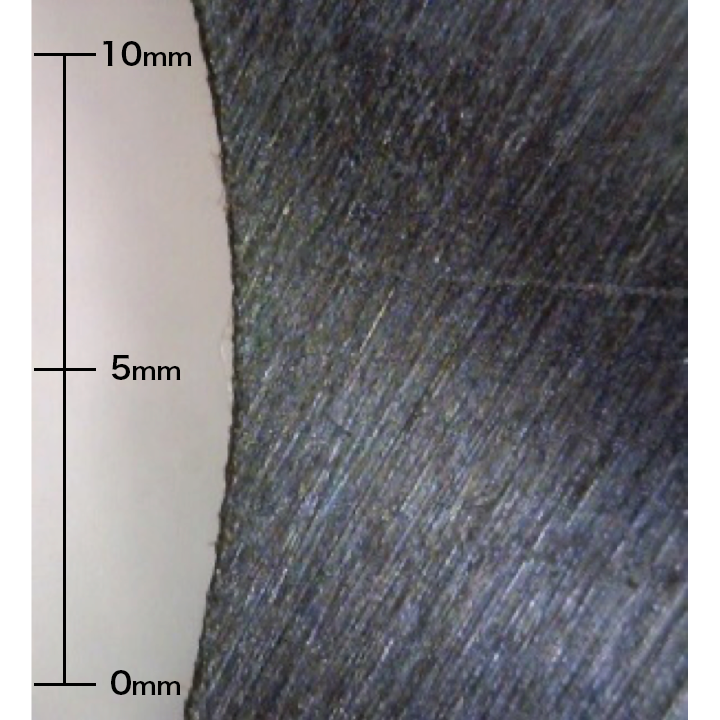

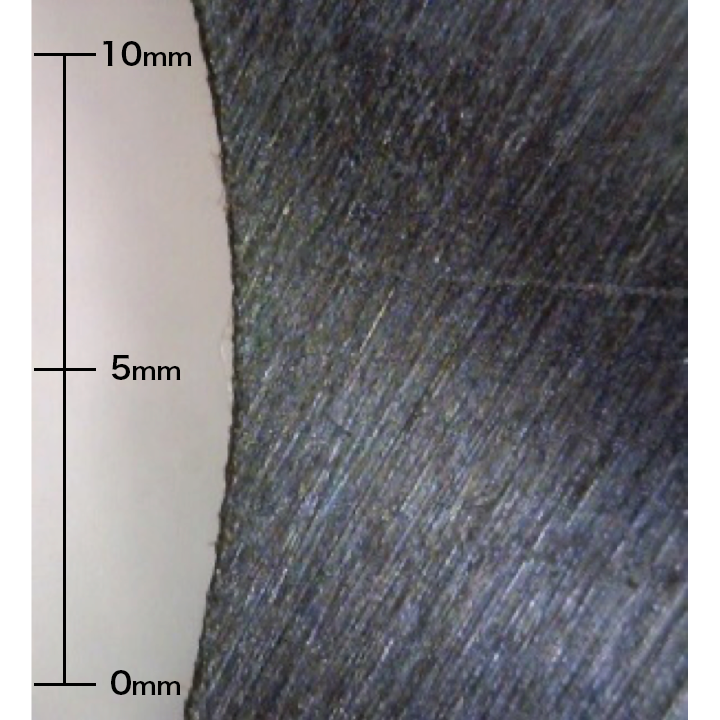

(c) Blanking machined cutter (made from plate material)

(Chinese product)

Before cutting test

After 500 times cutting test of 325 sq.-mm copper

When the test reached to 400 times cutting, this cutter was broken (spring on handles is broken).

The test was discontinued and this photo shows the blade condition at this time.

The edge (grinded part) is completely lost and broken.

It is afraid that the service life might come to the end before long if continuing usage.

The many ditches on the blade surface are scratch marks given by copper wire during the cutting test.

Before cutting test

Before cutting test

After 500 times cutting test of 325 sq.-mm copper wires

After 500 times cutting test of 325 sq.-mm copper wires Before cutting test

Before cutting test

After 500 times cutting test of 325 sq.-mm copper

After 500 times cutting test of 325 sq.-mm copper Before cutting test

Before cutting test

After 500 times cutting test of 325 sq.-mm copper

After 500 times cutting test of 325 sq.-mm copper