KOBAYASHI TOOL’s tool manufacturing technology

From manufacturing tools, such as box wrenches and other work tools, electric cutting tools such as cable cutters and various industrial edged tools to machine parts, we provide development, design, manufacturing, inspection and packaging services of all OEM, import and export products. As well, import and export options are also available.

We respond to our cliant’s needs as much as possible regarding matters of short delivery, cost reduction, small orders etc.

Also, based on drawings received from cliants, we provide prototype development and production services.

There are merits to this such as shortening the development period of the prototyping process, the planning process of new products, trial production processing at the research stage and mass production processing and prototyping in anticipation of mass production with strict confidentiality during development.

Using our one-stop production manufacturing system, from trial manufacturing to mass production and assembly, we have become experts at manufacturing products, considering manufacturing processes, and the work required during mass production.

We can consistently assemble composite parts, flexibly support assembly, packing, and shipping the final product as per your specific requests.

In addition to ordinary product packaging, we assemble and pack the final product as specified by the manufacturer.

Bundled work such as assembly of the final product, a check of neccesary accessory parts, instruction manuals and more are flexibly adapted per the cliant’s request.

For cliants and manufacturers, we contribute greatly to securing optimum stock and shipping in Just In Time.

Hot forging achieves overwhelming durability. More so than other manufacturing methods.

See Our Quality

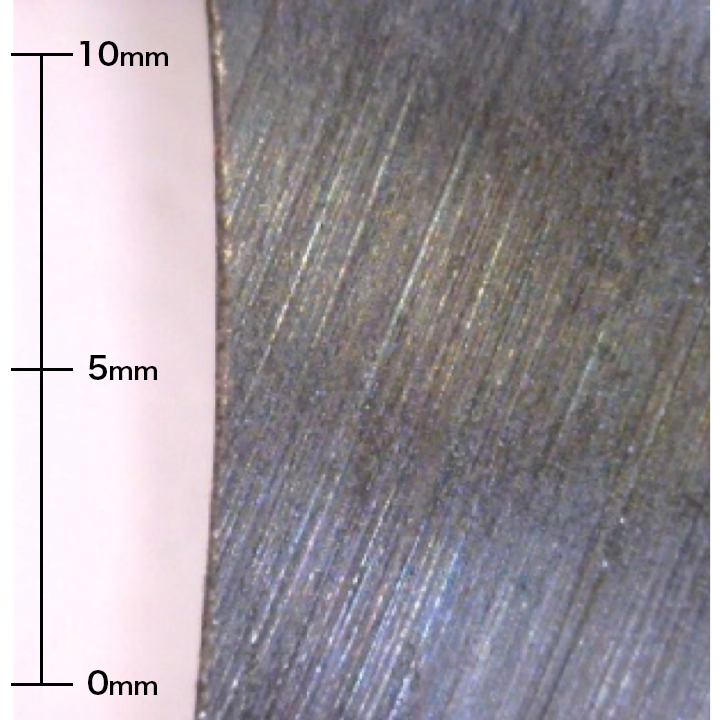

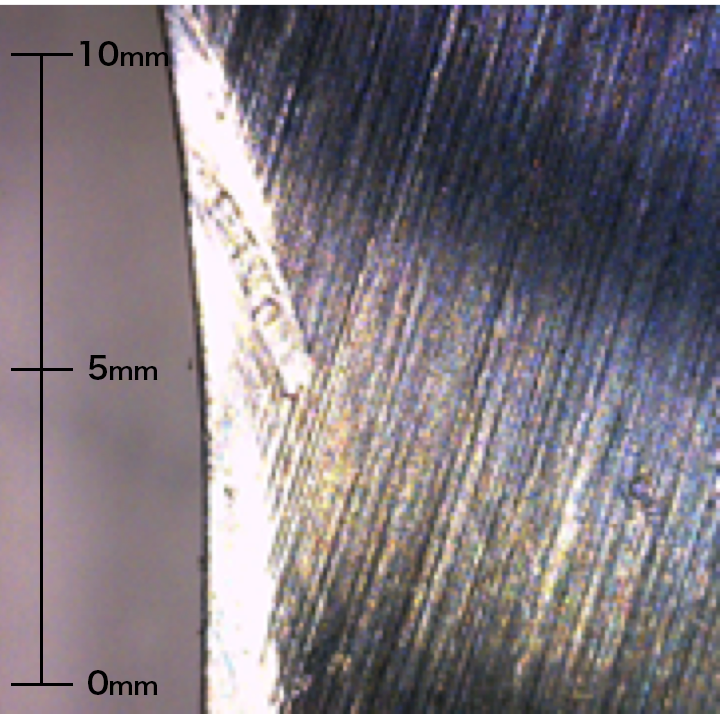

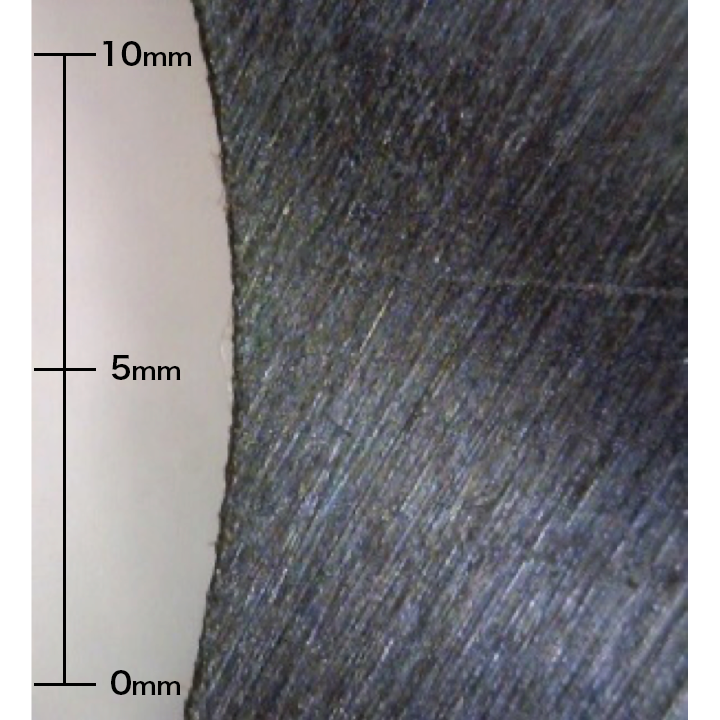

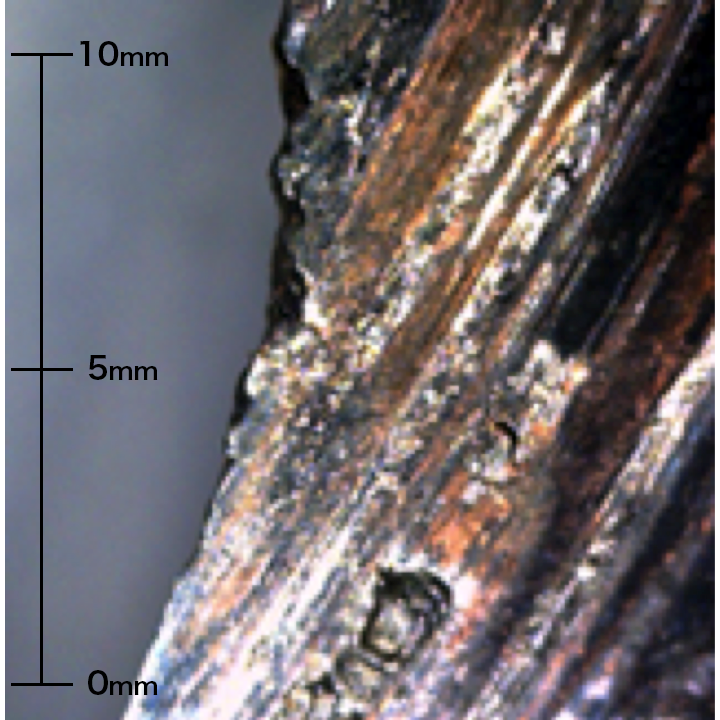

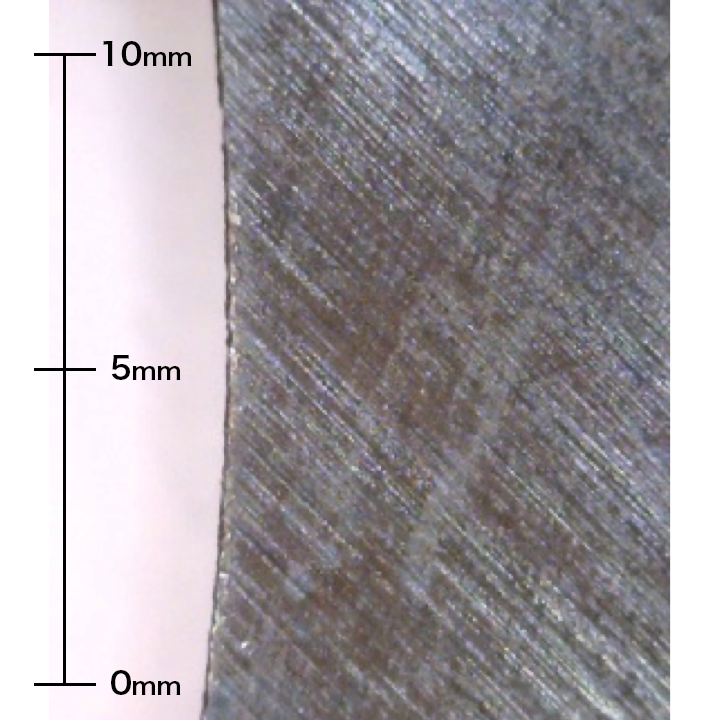

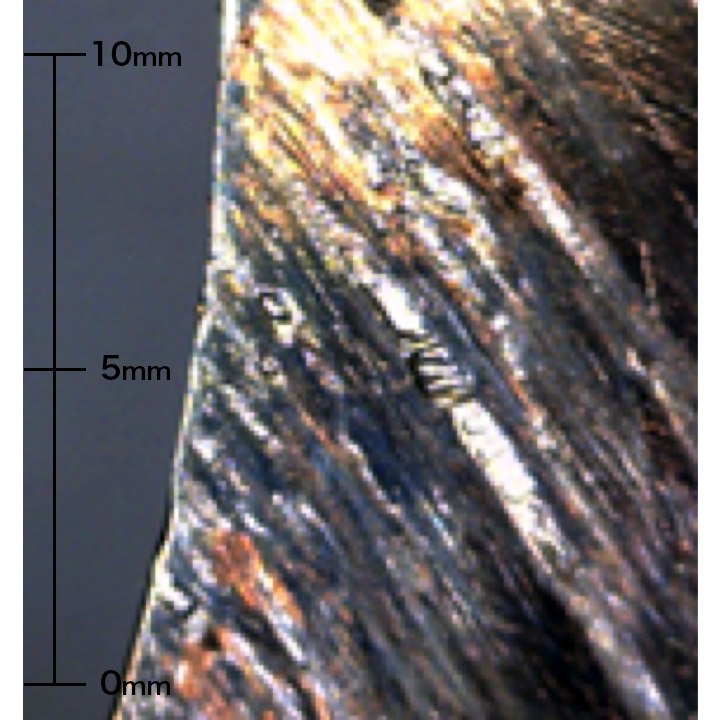

The microphotographs (50 magnification) below show the comparison of endurance test result ( 500 times cutting test of 325 sq.-mm copper wires) among; (a) Forged cutter (our products), (b) Lost wax molded cutter (Taiwan product) (c) Blanking machined cutter (made from plate material) (Chinese product)(a) Forged blade (our product)

Before cutting test

Before cutting test

After 500 times cutting test of 325 sq.-mm copper wires

After 500 times cutting test of 325 sq.-mm copper wires(b) Lost wax molded cutter (Taiwan product)

Before cutting test

Before cutting test

After 500 times cutting test of 325 sq.-mm copper

After 500 times cutting test of 325 sq.-mm copper(c) Blanking machined cutter (made from plate material) (Chinese product)

Before cutting test

Before cutting test

After 500 times cutting test of 325 sq.-mm copper

After 500 times cutting test of 325 sq.-mm copper